|

|

|

|

|

|

|

|

|

|

|

|

|

The Power of Standardardized Work

Click here for PDF version

|

|

|

Standardized Work: The Power of Consistency

One of the most important tools of lean manufacturing is standardized work. When starting a 5S program, the cleaning, organizing,

and developing of sustainable practices is done so the elements of work can be standardized. In lean product development

deployments, by developing and releasing design guidelines, we are in effect implementing standardized work for engineers.

The principles of lean and flow production do not work well when everyone is allowed to choose the method or sequence in which to

do the job; quality suffers, and productivity drops. This reduces throughput and the carefully developed production system develops

unanticipated bottlenecks.

Standardized Work: The Principles

Standardized work is a detailed, documented and visual system by which associates develop and follow a series of predefined process

steps. It should be used whenever the work requires completing a series of tasks. Production workers, shipping departments, and

warehousing teams all can benefit from implementing standardized work.

The detailed process steps which we call standardized work represent the current best practices for workers to follow in the

completion of their jobs. They are designed to minimize process variation introduced by the worker and to eliminate unnecessary

motion. This reduces waste, eases problem solving and enhances productivity within a particular job or set of jobs.

Without standardized work, continuous improvement activities are not manageable because processes which are in a constant state of

change cannot be improved. Detailed understanding of the steps needed to be taken to complete tasks is necessary to eliminate root

causes and permanently resolve issues. When workers utilize various methods to complete their work, it is not possible to develop

this understanding. Therefore, standardized work provides the baseline required for continuous improvement.

Like everything in lean manufacturing, standardized work is focused on what workers need to do to satisfy the customer. Unlike the

routers developed by engineering, which focus on the part and how it is processed, standardized work focuses on the workers and

what steps they must take to produce the part. Maintenance and improvement of the standardized work documentation is the

responsibility of the work teams.

With standardized work implemented, production workers, supervisors, and engineers no longer have to work from memory. The process

documentation provides a baseline, a standard which is referenced whenever someone new is trained on the job. The standard provides

consistent training results even if different managers or operators are used to train new workers.

The same principles apply even when new operators are not being trained to do the work. Over time, employees will develop shortcuts

to the process, sometimes developing bad habits. But with the baseline of standardized work, it becomes straightforward and easy to

complete regular process audits, following up by reinstructing workers on the proper and desired techniques or perhaps

institutionalizing the improvement workers have developed.

Standardized Work: The Elements

1. Takt Time - The Demand Rate of Production.

|

|

“Takt” is a German word which refers to the pace or drumbeat of a musical

composition. Imagine the chaos if each member of a band were to play the music at their own pace. The power of the music would

never be realized. Similarly, when production operations do not work at the same pace, chaos ensues.

Takt time provides definition to the relationship between work time available and the customer requirements, and enables us to be

aware of the time available to complete the job.

It is common to confuse takt time with cycle time, which is the actual elapsed time required to complete a task. However, they are

distinctly different concepts, and are not related.

|

|

|

Takt time is impacted only by customer demand and the amount of time available

for production. When demand rises, takt time drops. When available production time increases, takt time increases as well.

|

|

2. Cycle Time – The Production Rate

|

|

Cycle time tells us how often we can produce the product with current resources

and staffing. This isn’t the same as capacity or even detailed process analysis, but an accurate representation of how the line is

currently set up to run.

Cycle time calculations take into account the entire production quantities. When multiple lines are producing the same product,

then the

|

|

|

composite cycle time is less than the actual elapsed time of any individual

line.

The cycle time is the expected or historically average total production time per unit produced. On an assembly line or in a

workcell with multiple operators, each operator will have a time associated with completing the work he is doing. However, when

referring to the cycle time of the line, we are referencing the longest of these individual cycles. To reduce the cycle time of the

line, we won’t have to revamp the entire line, only the operation which is sets the pace.

|

|

3. Work Sequence - The Sequence of Tasks Followed to Complete the

Job.

There is a best method and sequence of process steps to produce any product. Even when the most efficient method is yet to be

found, we know it exists and that we can find it. This striving towards perfection is the foundation of lean thinking.

Focusing on work sequences is not unique to lean manufacturing. It has been a key part of manufacturing from the early days of the

industrial revolution, and is essential to the development and management of all mass production plants. But lean thinking

approaches are different in several ways.

-

Unlike traditional approaches, the work sequences are focused on the

production workers, not the parts. They instruct the operator on exactly what he is to do next, not just which process is to be

applied next.

-

Work sequences are developed by those doing the work. Although it is typical

for management or engineering to actually document the process steps, they are developed by the workers. Engineering, quality,

and other functional groups are consulted to ensure the steps will yield the desired results, but the driving force is the

production worker.

-

Standardized work utilizes visual controls. The sequences are defined

primarily by visual images. When done properly, the process should be able to be followed even by someone who does not speak

the language well.

-

Standardized work sequences are audited. Management communicates commitment

and belief in the process by regularly checking to ensure it is being followed.

|

|

Standardized Work: The Tools

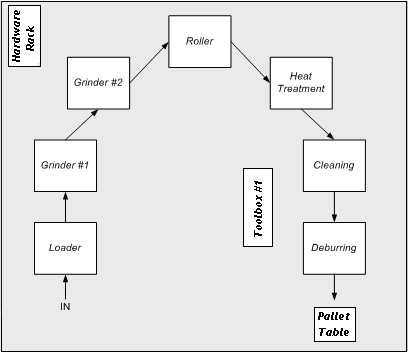

1. Standardized Work Analysis Sheet – Cell Layout

|

|

Organization of the workcell is an important part of the design of a process.

When a cell or assembly line starts to degrade or be neglected, one of the initial symptoms is equipment and tools that are not

being returned to their proper locations. The cell layout provides the baseline, or standard, for the cell. The team uses it as a

reference when organizing or cleaning the work cell. Process audits include checking to ensure that the cell layout is being

maintained.

|

|

|

When completing cell layouts, it is important to show everything in the workcell

in their proper locations. This includes work tables, staging tables, storage and part racks, equipment locations, pallet locations

and tool boxes.

When the workcell has a containment area, it should also be shown on the layout.

|

|

2. Time Observation

Nearly a century ago, Fredrick Taylor started the practice of time observation when he began using the scientific method to

establish time standards in manufacturing. In lean manufacturing, we focus more on system level performance than individual process

efficiencies. But the understanding of work elements and the time required to complete them are an important part of lean

manufacturing.

Time balancing processes so that cycle times closely match takt times is essential to eliminating wasted resources. All workers in

a cell must have equal or nearly equal amounts of work, or productivity of the line will suffer. When the cycle time of a workcell

exceeds the takt time for the cell, then late shipments, shortages, or excessive overtime will result. If the cycle time of the

workcell is less than takt time, either overproduction or efficiency reduction will result. Without detailed knowledge of cycle

times and set-up or change over times, such process balancing is not possible. Time observation is the tool that provides the

detailed knowledge.

While time observation approaches are similar in lean and traditional manufacturing environments, there are significant

differences.

-

Lean manufacturing time observations are conducted to optimize and balance

the work within the cell and to aid in the effort to reduce overall lead time - traditional manufacturing uses them to

establish time standards. While it is true that lean manufacturing systems sometimes temporarily establish time standards, the

overall continuous improvement activities will quickly render such standards obsolete.

-

Lean systems use production workers to conduct the time observations. They

aren’t conducted by supervisors, manufacturing engineers, industrial engineers, or others who come into the workplace to judge

or dictate how team members perform their jobs.

-

In lean systems, we study the process, never the worker doing the

job.

|

|

|

|

3. Standardized Work Combination Sheet

The standardized work combination sheet (SWCS) brings many of the lean tools together. It is a graphical representation of the

process for visual control, emphasizing the work sequences of the operation. The SWCS brings together all elements of the process,

including the time element, and shows the actual sequence of completing the work. It shows the manual work, the automatic or

machine work, the walking or non-value added time, and the takt time. It is distinctly different from the work instructions or

elements, which define the process methodology. Typically, hand work is denoted by a solid line, machine time by a dotted or dashed

line, walk and other non-value added time by a wavy or red line. Takt time is denoted by a vertical, solid line on the right side

of the sheet.

In lean operations, we often find cycle clocks which display the elapsed time of the current cycle. Standardized Work Combination

Sheets work with these cycle clocks to provide an excellent visual control mechanism. A glance at the SWCS can tell a worker where

they should be in the work cycle and allow for proper pacing to stay on schedule. They provide a management tool which easily

facilitates auditing of the process. Finally, they are a great aid to workers, especially when operations run close to takt

time.

|

|

|

|

4. Operator / Machine Balance Charts

Many work cells and nearly all assembly lines require multiple operations and workers to do a variety of tasks or work sequences to

actually produce products. The cycle time of each of these operations can be easily determined using the time observation methods

discussed above.

The operator / machine balance chart is used to quickly compare the work load on the resources of the work cell to each other and

to takt time. Like the other standardized work tools, it is a visual representation of the process. The operator balance chart

provides a picture of the time required to conduct every operation in the work cell. Balance charts show operations which require

more or less time than is available, and also show the relative loading of each operation. To be in balance, the operator / machine

balance chart needs to provide nearly equal workload to each operator, and to develop a cycle time which closely matches the cell

takt time.

A balance chart is a bar chart which shows the time required for each operation in the cell. The value of each bar is the time

required for that particular operation. To be effective, the balance chart must also show takt time, which is represented by a

horizontal line on the chart. Any deviation of the operation bars to the takt time line is waste; an opportunity for improvement

using lean manufacturing methodologies.

|

|

|

|

Standardized Work: The Conclusion

Standardized work is a foundational element of lean manufacturing methodologies. Without it, the gains made from organizing work

cells, creating flow production, and starting continuous improvement teams will only be temporary.

Implementing standardized work is never easy. The detail requirements and information have to be uncovered, revealing questions and

new concerns. Time observation is time consuming, and often an unpopular activity on the plant floor. Standardized work activities

are never finished. Lean manufacturing strives, but never achieves perfection, and with every new step towards perfection, the

standardized work changes.

But the hard work and the constant striving to improve are worthwhile. Improved quality, productivity, safety and customer

satisfaction is the reward.

|

View site map

|

|