|

|

|

|

|

|

|

|

|

|

|

|

|

Establishing Lean Metrics – A Quick Start to your Data

Based Reporting System

Click

here for PDF version

|

|

|

Strategic Foundation

In my previous white paper, “Establishing Lean

Metrics – Using the Four Panel Approach as a Foundation for a Lean

Scorecard”, I outlined the essential steps required to establish a data

based reporting system. It is necessary to systematically define the categories

for measurement, and then develop a vision statement, objectives, measures, and

strategy for each category.

While establishing these foundational steps will dramatically increase the

effectiveness of a metrics system, additional tools are needed in order to make

the system functional. The system relies on charts and graphs to communicate

issues. It relies on discipline from management and staff to effectively drive

continuous improvement. The essentials of putting this visual reporting and

management system in place are outlined in the following pages.

Metrics Reporting System

One of the outputs from the Four Panel work sessions is a list of measures. But

each of the measures needs a reporting system, i.e. set of charts, that includes

these four elements;

- Demonstrate performance changes over time and compare performance to

targets (Trend Chart)

- Illustrate clearly the current issues and their relative severity

(Pareto Chart)

- Show historical trends of issues and the relative severity of past issues

(Paynter Matrix)

- Record actions that have been taken and report the effectiveness of those

actions. (Action Log)

These requirements can be easily satisfied via a single, one page report. A

simple Excel spreadsheet allows for tracking and charting the data with relative

ease. A sample of the finished product is shown, each of the measures will

require a sheet with these four charts. I have developed a template for this

which you can download here.

To make charts more powerful and easier to use, make sure to clearly label the

charts and the units used, and avoid complex formulas or transformation of the

data; stick with the data in the form most likely to be understood by

everyone.

|

|

|

|

|

|

|

|

|

|

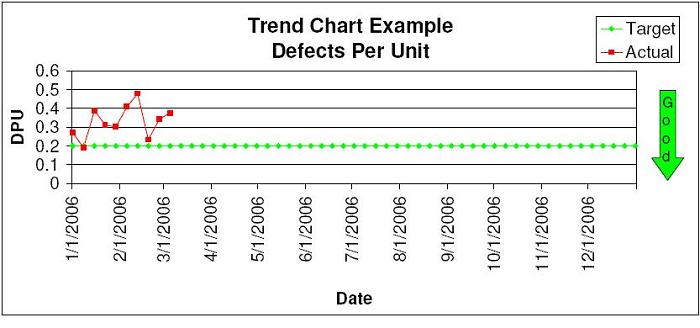

Trend Charts

Sometimes known as run charts, trend charts are used to show changes in

performance over time. Run charts are used to provide a visual indicator of

performance. Since there will always be some variation in results, displaying

them over time makes it easier to see and understand how our actions are changing

the results, and how we are performing relative to the target.

Resist the temptation to set the time periods too short for the individual data

points on the trend chart. Short time periods can make it difficult to see the

real trends. Occasionally, it is acceptable to use time periods as short as one

week, but generally monthly buckets are preferred.

When setting up trend charts, be sure to include and clearly label the targeted

performance. Place an arrow labeled “GOOD” and indicate the direction the results

are desired to move.

To make your trend charts the best they can be, make sure to follow these

guidelines.

- Label the chart with a brief, but descriptive title.

- Label the Y Axis with the units being used. Label the X Axis with the time

periods.

- Don’t crowd the data to the top or the bottom. Use most of the range

available, but allow for future movement. Don’t include impossible numbers.

(i.e. 110% On-Time Delivery)

- Don’t change the scale of the chart once established. These same reports

will be used month after month. Changing scales tends to confuse and make

interpretations more difficult.

- Use one chart per measure. Don’t add extraneous data or try to combine

related measures on a single chart.

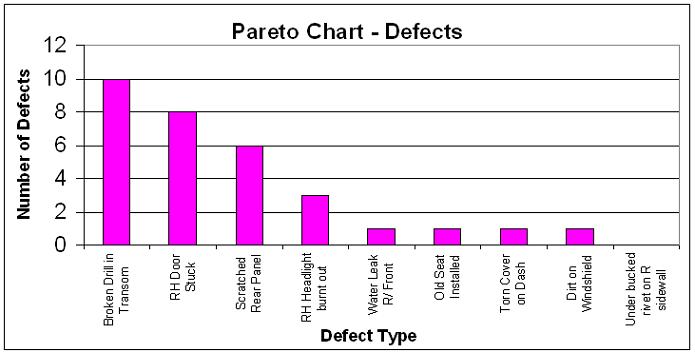

Pareto Charts

A Pareto chart is a special form of a bar chart that puts items in order from

highest to lowest (occurrence, time, cost, etc.). It is the visual manifestation

of the Pareto Principle which states that when several factors effect a

situation, 20% of factors will account for 80% of the issues.

Pareto charts are valuable because they help us to quickly identify the vital few

factors on which to focus in order to maximize our overall results. They break

big problems into smaller pieces and help direct our limited resources.

Pareto charts always present the data from highest to lowest. If a bar chart

doesn’t present the data in this format, then it isn’t a Pareto chart. The data

on which Pareto charts are built can usually be categorized in multiple ways. For

example, should the quality data be sorted by number of occurrences, by total

cost, or by its impact on the customer? Chose carefully, the way you decide will

impact the actions which will be taken down the road.

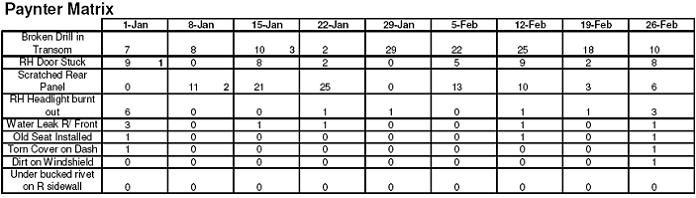

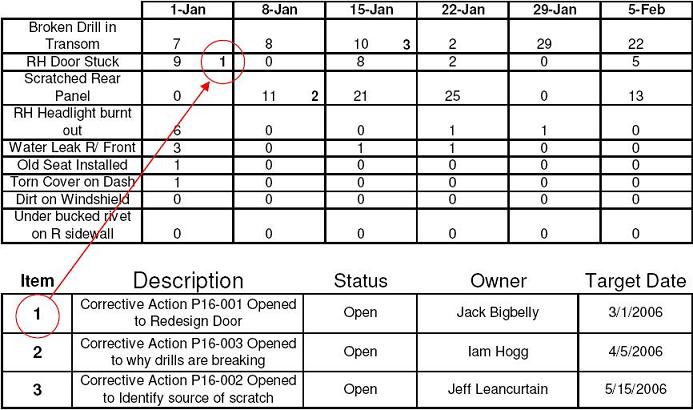

Paynter Matrix

The Paynter Matrix is a tool which illustrates the effectiveness of containment

and corrective actions. It allows us to track the cumulative effect of corrective

actions on the results. It actually uses the same data as the Pareto charts, but

adds a time element by showing the data for previous time periods.

It is essentially a matrix with categories in the leftmost column with a time

series in the succeeding columns. When corrective actions are implemented for a

particular category, the action is noted on the time series. When the corrective

action is effective, there will be a corresponding improvement in the

results.

|

|

|

|

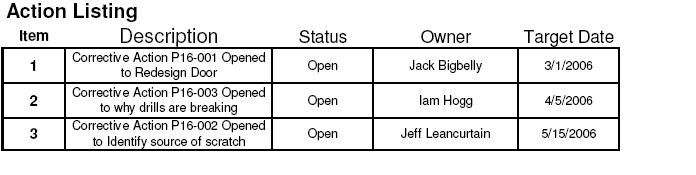

Action Log

The action log is a tool for recording and tracking required actions. It provides

clarity for what is to be done, a mechanism to conduct regular review of the

actions and their status, defines the responsibility for the actions and provides

a date certain for completion. The action log is the tool that connects the

metrics system to the continuous improvement process.

Establishing Discipline and Conducting Reviews

The data based reporting systems are of no use if we don’t follow through and

establish the discipline to use them. In my visits to plants, it is common to

find measurement systems that have been abandoned; the charts are posted on the

bulletin boards, but the data is out of date. It just serves as a reminder of

another failed attempt at improving our operations.

Establishing the foundation and the charts for a measurement system is fairly

easy. Most companies and experienced managers can define the vision, objectives,

measurements, and strategy in a few days. Within a couple of weeks, the charts

and spreadsheets can be set up and put in place. But this effort is valueless if

the tools aren’t used once deployed.

If you want your measurement system to beat the trends and really become a tool

that drives improvement, here are some tips for making your data based reporting

system more successful:

- Get buy-in from facility managers while developing the system. Don’t

develop it in a vacuum and force it down their throats. Involvement in the

process is the key to success.

- Follow up. This is important. Travel to the manufacturing facilities and

review the results face-to-face. Don’t fall into the trap of just following up

by telephone, or even worse - just reviewing reports submitted by e-mail.

Visiting the plant to review the results will emphasize their importance and

will dramatically improve results.

- Hold the operations team accountable for the results. Performance on the

metrics should be reflected in bonuses, performance reviews or other

performance based rewards. However, this only works when there is buy-in from

the facility team on the performance targets. They cannot be held accountable

(or rewarded) for performance on metrics which are not achievable or those that

are not in their direct control.

- Make the metrics clear and easy to understand. Clear definition of exactly

what data to collect and how to calculate results will help prevent

manipulation. When employees can see how their individual actions improve the

results, they will respond in a positive manner.

- Insist that local management include first line supervisors and hourly

associates in the reviews. The more they understand the measures and why they

are important, the sooner improvement will be realized. Hourly associates

should regularly be asked to present the results and the action steps to the

management team – it can help break down barriers and establish open

communications.

- Always demand action plans, improvement teams, workcell kaizens, or other

proven problem resolution methodologies be employed to resolve issues once

identified. This system can help drive improvements in your facility, but only

if you use it as a tool to drive continuous improvement.

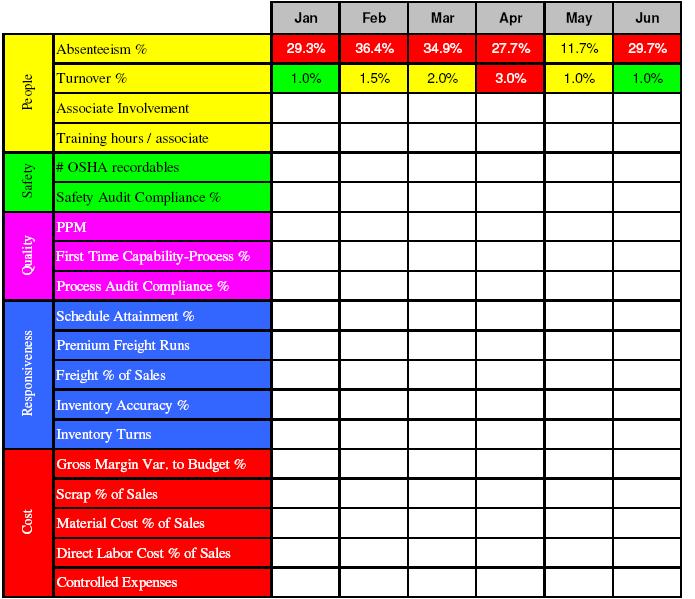

Use a Scorecard to Summarize and Report to Management

It isn’t uncommon for these systems to have 20 to 25 individual measures. In

order to see trends that may occur between the measures, and to rapidly report

facility results to executive teams, it is necessary to consolidate the results

on a single report; commonly referred to as a scorecard.

The data for the scorecard comes directly from the trend chart. The monthly

results from the trend chart are inserted into the appropriate cells in the

scorecard and color coded; green - results are on track for the month and for the

year; yellow – results are on track for the month, but not for the year; red –

the results are not on track for the month or for the year.

|

|

|

|

The entire system is very visual. The trend charts and the Pareto charts display

results in a visual format. This visual orientation continues with the scorecard.

In addition to color coding of the results, the categories themselves are color

coded.

- People – yellow

- Safety – green

- Quality – purple

- Responsiveness – blue

- Cost / Finance – red

These tools, combined with the discipline required to use them, the proper

application of lean manufacturing techniques, problem solving methodologies, and

mistake proofing methodologies can greatly increase the velocity of change within

your operations. It isn’t magic, it requires much work and a willingness to

change, but the results can be spectacular.

|

View site map

|

|